Dongguan Kinggold Industry Co.,Ltd.

Dongguan Kinggold Industry Co., Ltd called KGI for short, which was founded in 2003 and located in the "world factory" Dongguan. The factory covers an area around 12000㎡ and is a comprehensive industrial enterprise committed to diversified development. Relying on 20+ years of experience in stamping parts production and management , KGI has invested and integrated all kinds of supply chains to provide customers with industry-wide services, such as CNC machining, zinc&aluminum die casting, aluminum extrusion, sheet metal, spring, plastic &silicone, finished and semi-finished products assembling,etc. KGI is always committed to provide global customers with customized one-stop solutions from product R&D, mold manufacturing, production and procurement, assembling, testing, packaging to transportation and exportation.

KGI has always been committed to technology research development,production capacity improvement and cost control, the company is equipped with a professional engineering team, all molds are developed,designed and produced independently,we also brought in a small laser cutting machine for rapid prototyping to meet the client’s test demand in the initial phase of the project. KGI has a number of precision stamping machines with a daily output of millions of pieces, and constantly streamlines and optimizes various production processes, especially optimizing the whole process of EMI RF shielding products, from stamping,cleaning, to automatic inspection and tape&reel packaging integration,as well as optimizing the technology and production capacity of various customized stamping parts. At the same time, relying on many years of production management experience and professional engineering & quality control capabilities, we come to a special subcontract model,that is in house stamping,CNC machining ,assembling etc combine with subcontracted die casting,aluminum extrusion,sheet metal,spring,plastic&silicon,surface treatment etc, so as to a complicated project which contains a variety of manufacturing processes can be completed in a compact and orderly manner under the professional splitting and combing of KGI, and finally unified to KGI to complete the inspection,sorting, packaging and transportation, so that the whole project can be successfully completed with the lowest manufacturing cost, the highest production efficiency and the best quality control. After years of development,our diversified products have taken up more than 60%, 90% been exported abroad and keep increasing year by year.

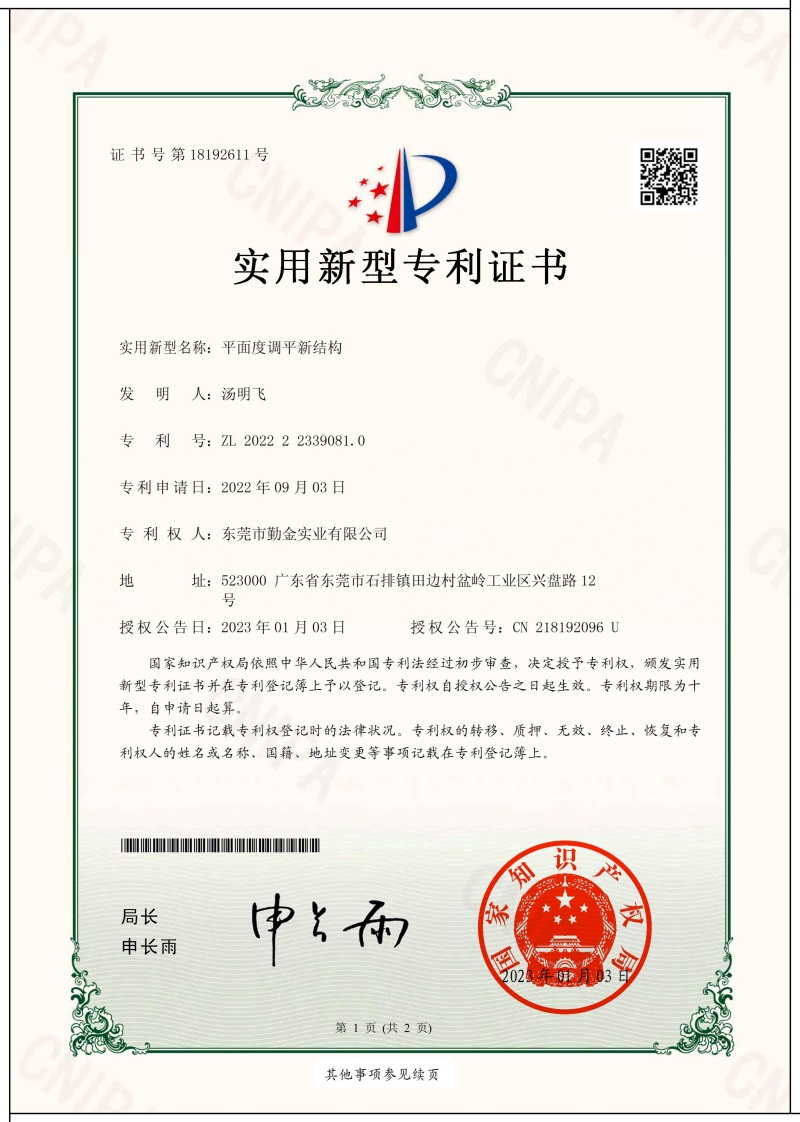

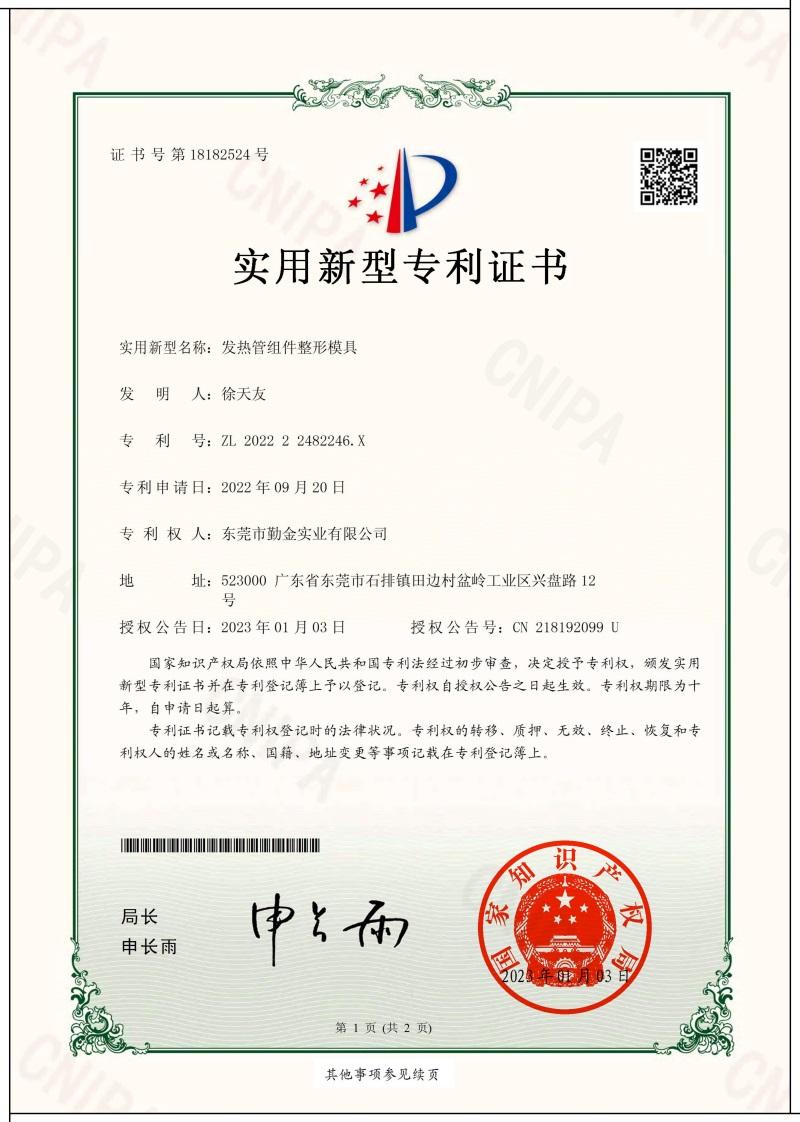

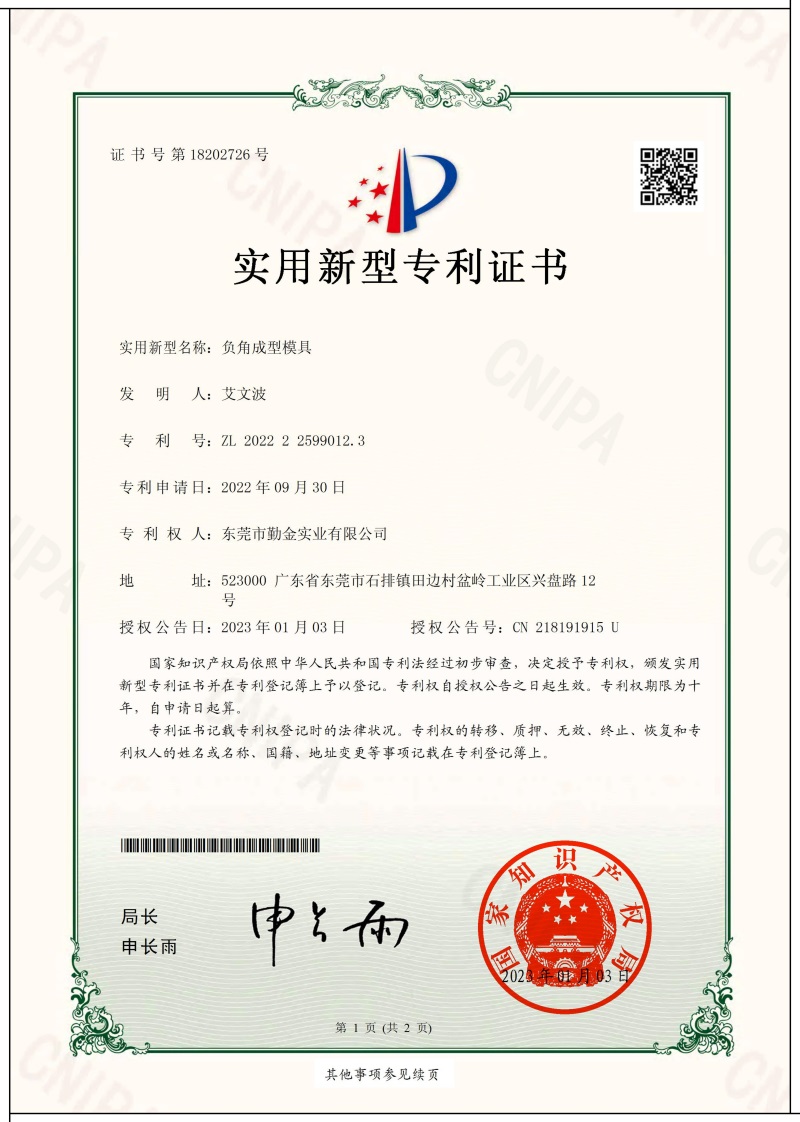

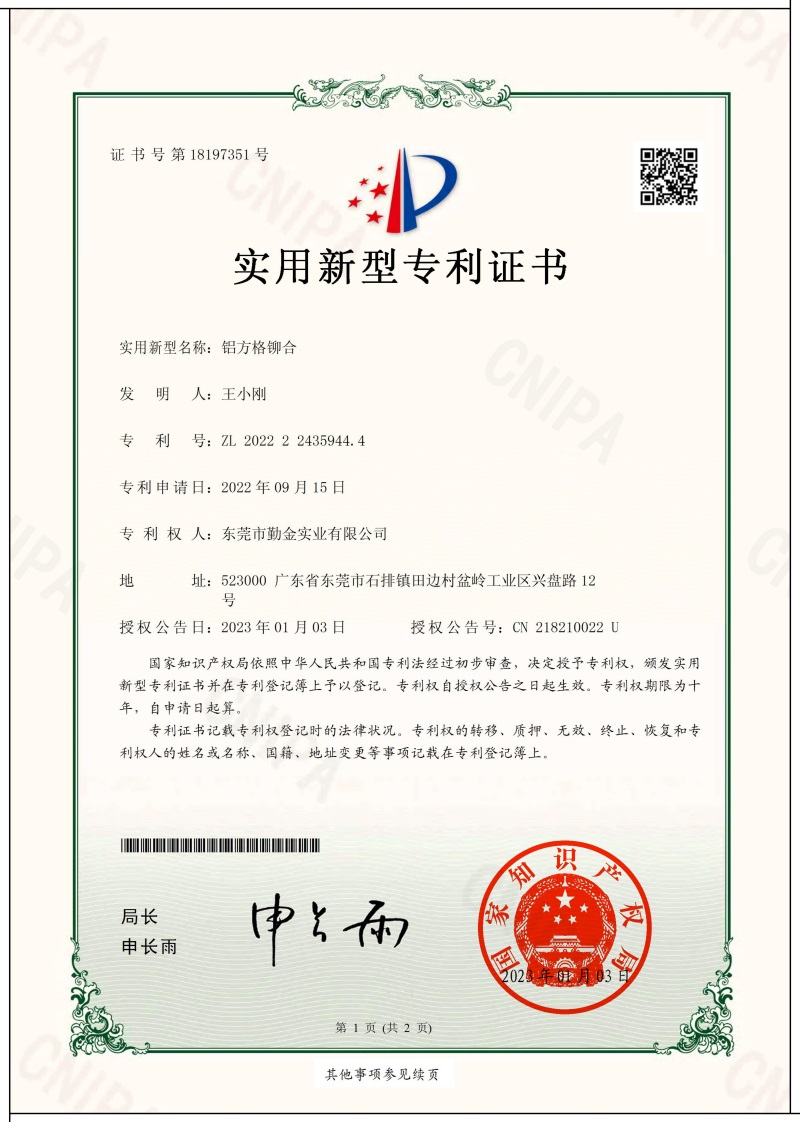

KGI has passed ISO9001 and IATF 16949 certifications, also gotten various technical patents. And in order to meet the needs of diversified products, we are equipped with perfect inspection equipment, such as CMM, 2.5D automatic image measuring instrument, Japan imported Keyence measuring instrument, film thickness tester,salt spray test machine,colorimeter, etc. All inspection reports are permanently stored under electronic network management, which is convenient for tracking and traceability in future, and has laid a solid quality foundation of the development of diversified products.

KGI attaches great importance to team building, is equipped with complete engineering, quotation, procurement, quality, production and sales teams,and fully implements ERP digital management which provides strong data support for continuous cost reduction and efficiency improvement. In addition,our team also regularly visit customers abroad for better understanding customers and market needs, as well as ensuring Made in China to be closer to the needs of international market in real time.

Besides doing a good job in products and services, KGI also pays much attention to employee welfare and social contribution. We provide employees with regular physical examinations, offer education and skill upgrading grants, and establish public welfare organizations, while not only enriches our company culture, but also makes a modest contribution to the society.

KGI looks forward to your visit!